Categories

Speciality Areas

Naturally, sheepskin is used for pressure and skin care

The world uses a lot of plastics in pressure care products since they are easy to work with and great for mass production. In recent years, there has been a greater focus on the downsides of fossil fuel-based materials as we face up to the current climate emergency. So, what choices can we exercise to reduce our use of oil-based materials and what are the benefits of going back to using natural materials? In this article, we look at the advantages of an inexpensive and readily available natural material, namely real wool, over synthetic materials, when used in pressure care.

In England, the cost to the NHS of treating pressure ulcers is over £3 billion a year, representing four per cent of total expenditure. Preventing the occurrence of a good number of these ulcers is considered to be achievable (see box) and the costs of prevention are a lot less than the costs to cure (the latter at a conservative average cost of £14,000 per ulcer), not to mention the impact on a person’s quality of life that having an ulcer represents.

Pressure ulcers or injuries to the skin arise from ‘external’ influences on the skin from a mix of pressure, shear strain heat, and moisture. People who are relatively immobile and/or have ‘internal’ influences – such as older age, diabetes or drug regimes – may be more susceptible to skin breakdown. It is these clients for whom prevention is of critical consideration. In this article, we look at the benefits of using wool-based products, rather than those made from man-made fibres, to give skin the best protection.

A history of sheepskin

Natural sheepskins used to be widely used as an effective, user friendly and easily accessible means of pressure ulcer prevention. Then increased awareness of infection prevention came along: traditional methods of tanning sheep skins meant that they could not be washed at the higher temperatures needed to kill microbial contamination. Prescribers moved over to artificial sheepskins made from synthetic fibres or low density wool, however, these materials have been found to be relatively ineffective for pressure and skin care and understandably were deprecated in NICE guidelines. CSIRO in Australia tackled the challenge of thermally disinfectable sheepskin by developing a new tanning technique which meant that sheepskins could be washed at up to 80C, at least 30 times, without shrinking, and at the same time the skins were urea-resistant. Urea (found in our sweat and urine) otherwise dries out the leather and makes it crack. This methodology was incorporated into the Australian AS4480.1 as a standard for producing ‘medical sheepskins’ in 1998. However, the skins do still need to be washed with wool wash, since enzymatic detergents will attack the leather.

These medical sheepskins have been shown to be clinically effective at reducing the incidence of pressure ulcers in a number of Randomised Clinical Trials (RCTs) and, as a result, NICE upgraded its advice so that it now indicates that medical sheepskins are an acceptable means of pressure care. The MDA study in 2004 (MHRA 04101-0) of bed overlays showed that medical sheepskins matched or outperformed the other tested overlays for heel pressure distribution and heat transfer characteristics, for example.

Efficacy of sheepskin

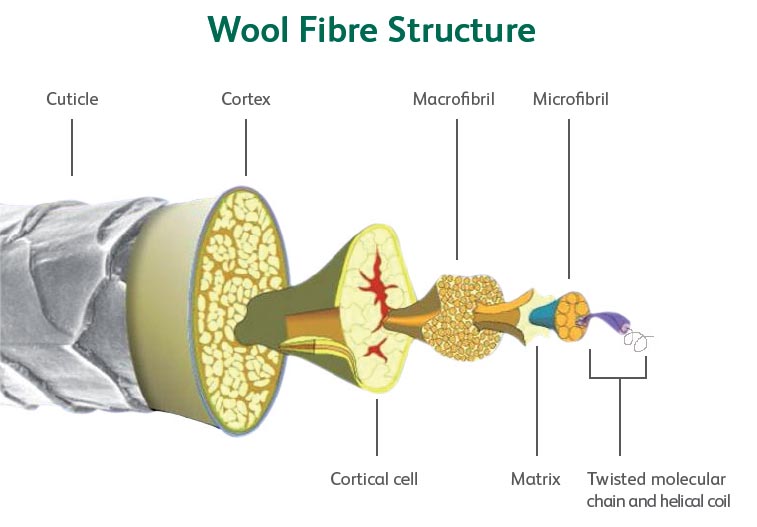

So why can wool protect the skin where man-made fibres cannot? The reason is that each wool fibre is made up of multiple layers of material (see Fig. 1), each of which supplies a separate benefit.

The outer cuticle layer allows the wool fibres to slide over each other. This sliding absorbs the shear strain created by a person’s body moving over the sheepskin and reduces frictional forces on the person’s skin. The cuticle also allows air to be caught between the wool fibres, allowing better dissipation of heat and moisture, which does not occur with man-made fibres.

The cortical materials give wool fibres the ability to take up to a third of their weight in water vapour and thus help to wick away macerating moisture from the skin, whereas man-made fibres are generally hydrophobic, leaving water vapour with nowhere to go, but sit against the skin. Laboratory testing has also shown that the higher the density of the wool, the more water vapour that is able to be taken up.

And then we come to the helical core, which is what gives wool its bounciness and resilience – its ability to form around and envelop the skin tissues, and thereby spread the pressure forces on the skin over a wider area. Again, the higher the density of the wool, the better the immersion and envelopment properties. The thickness of the fibres is also critical here and they need to be 28±1 microns thick to give them their optimum resilience and not get flattened. Man-made fibres do not provide this resilience.

Therefore, wool wins over manmade fibres hands down.

Fabric-backed sheepskin

Real leather medical sheepskins became the material of choice once the Australian standard was published and the RCTs were carried out. The success of medical sheepskins came because the density of the wool, as outlined above, is important and because certain crossbreeds of sheep are able to produce a density of wool at up to 1000-1200 grams per square metre (gsm), higher than the best that man could produce at up to 7-800 gsm, with real wool knitted into a fabric back.

This all changed when an Australian company, Healthcare Innovations Australia, developed a technique to knit in real wool at a density of 1900 gsm into their XD1900 material. This XD1900 matches medical sheepskins for sliding resistance (shear and friction) properties and exceeds at water vapour and pressure redistribution properties. Not only that, XD1900 can be washed at 100C and with enzymatic detergents. It is also kinder to the environment since it does not require the use of noxious tanning chemicals in its production. Thus, we now have available products made from a natural and renewable material that provides superior skin care and is better for the environment, going back to basics. These natural wool products are also well accepted by clients as, despite their efficacy, they appear attractive and homely in use.