Categories

Speciality Areas

What makes a good positioning belt? Part 4: Wheelchair attachments

The first consideration of a seating system is usually its cushion. This aspect has been covered elsewhere in our downloadable booklet “What makes a good cushion?” An equally important component of many seating systems is the array of postural support devices (PSDs) provided with the seating to complement the cushion and back support elements. This is the fourth in the series covering PSDs, where we look at the means to attach positioning belts in the position you require them to be fixed, to provide the desired results, despite the presence of in-the-way ‘furniture’ on a chair, and without needing to drill into the framework.

The previous articles in this series covered the anatomy of a pelvic positioning belt; choosing and adjusting a pelvic positioning belt; and the features and benefits of different belt closures. However, to achieve optimal positioning, it is important that the belt is attached to the wheelchair in such a place as the biomechanical forces on the occupant’s body are providing the best anatomical positioning of the occupant while providing optimal functional opportunities.

The restrictions that we need to work around are that many wheelchair manufacturers do not supply any predrilled holes in the ideal places; often the chairs have accessories attached to the framework exactly where you wish to attach the belt; the manufacturers do not normally allow you to drill into the framework of the wheelchair without affecting the warranty; and, importantly, a fixed attachment point does not allow for changing positions as the occupant’s needs change.

Correct belt attachment points

Fixing a pelvic positioning belt in the correct position for that occupant is absolutely critical for the safety and optimum functionality of the occupant.

Wheelchairs (as delivered by their manufacturers) may well have a simple belt fitted at the junction between the back support and the seat cushion support structure. This is not guidance as to where the belt should be placed when the occupant is in the chair. Since the manufacturer does not know where the positioning belt is to be positioned correctly for each occupant, this is just an easy place to fix the belt for transport from the factory. The belt itself also may be insufficient for the client’s needs (see earlier articles in this series).

Sadly, wheelchair users around the world have died from suffocation due to slipping (submarining) under their positioning belts, sometimes due to these belts having been left at the back support-seat junction giving a 45 degree angle across the pelvis, in the position where you might expect a transport safety belt (restraint). This was the reason that BS 86251 was produced, to give guidance and instruction as to the optimum placement of belts and harnesses to cover a client’s positioning needs, and, importantly, reducing the risks of harm to the wheelchair occupant.

This article summarises the material in Annex D of BS 8625 which suggests various options to address the challenges of getting the pelvic positioning belt in the right position.

What to attach to

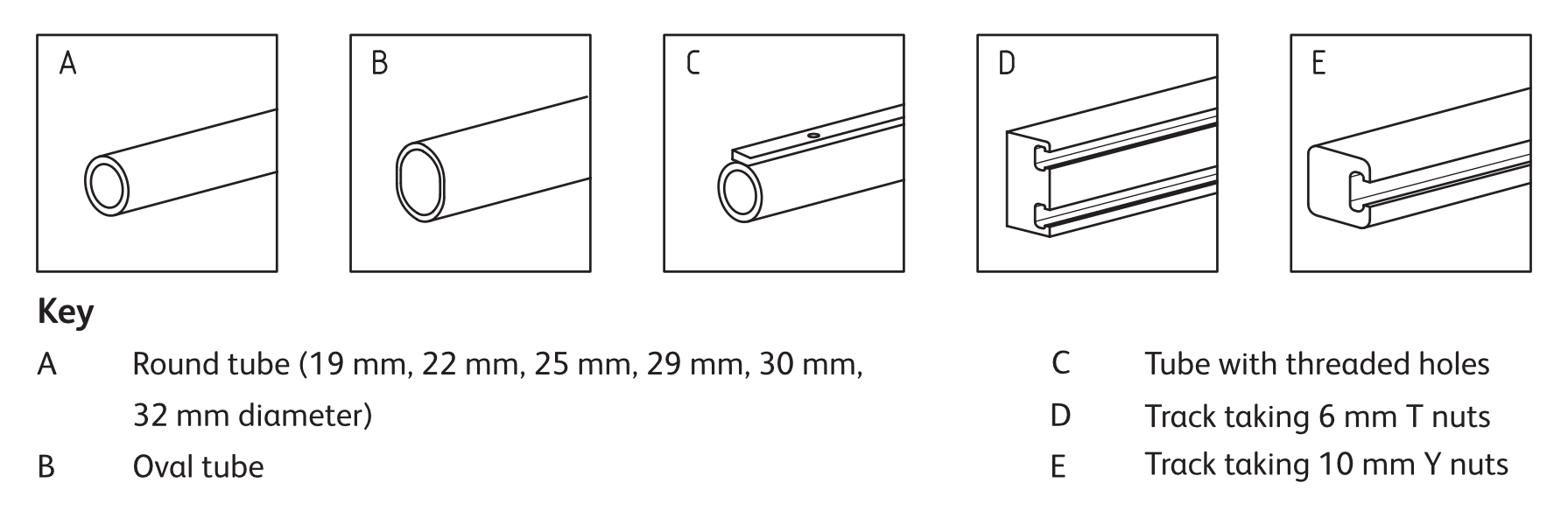

The first challenge is the variety of tubing and extrusions used by different wheelchair manufacturers, as illustrated in Figure 1. It would appear that most wheelchair manufacturers select the materials for their chair frameworks for structural support of the occupant, for the wheelchair accessories such as wheels and casters, and, presumably, for aesthetics, but too few seem to bear in mind the range of positions and functions required for the different postural support devices which will be mounted on the chair.

wheelchair manufacturers select the materials for their chair frameworks for structural support of the occupant, for the positioning wheelchair accessories such as wheels and casters, and, presumably, for aesthetics, but too few seem to bear in mind the range of positions and functions required for the different postural support devices which will be mounted on the chair.

What to attach with

There are various commercially available accessories that cover the options listed in Annex D of BS 8625, and these are outlined below. There are YouTube videos available (courtesy of Bodypoint Inc) to give guidance as how to mount the Bodypoint versions of these accessories, if you are any way unsure around how to go about it7. The relevant link is indicated for each accessory, and is marked videox, and the link is listed in the reference list at the end of the article.

Clamps

Most manual wheelchairs have circular tubing (Figure 1 Type A), and the simplest way to get around these is with a circular clamp with a threaded bolt to hold them in place (Figure 2). These are usually designed for 25mm (1”) tubing, and have shims for use with 19 or 22 mm tubing. (Video2).

Figure 2: Circular clamp

Where there is circular tubing that it is not possible for the clamp to get all the way around the tubing (e.g. there’s the seat canvas or an arm support in the way), a frame clamp (Figure 3) or a band clamp (Figure 4) are good options. A frame clamp has an open-jaw: The clamp splits into two parts, and is adjusted by a bolt with a hollow centre to join the two parts. The hollow centre is threaded to take a bolt to fasten the support to the clamp. (Video3).

A band clamp is a flexible stainless spring steel that fits into tight gaps under attachments (e.g. a seat canvas) on a wide variety of frames. The clamp splits into two parts, and is adjusted by a bolt with a hollow centre to join the two parts. The hollow centre is threaded to take a bolt to fasten the support to the clamp. It is suitable for tubing Types A and B in Figure 1. (Video4).

Mounting brackets

A seat tube mounting bracket is a mounting solution for chairs with sling seat upholstery with pre-existing threaded holes (e.g. Type C and D in Figure 1), or a solid seat base (see Figure 5). Elongated holes allow for fine adjustment of the position for attaching the support, and holes are positioned to bolt the wheelchair webbing attachments onto the bracket. The brackets illustrated provide for a snug fit around the sides of a cushion, and can help to keep it in place. (Video5).

Figure 5: Seat tube mounting brackets

T-slot fastener kits

Many power wheelchairs are supplied with a single or double slotted extrusion at the side of the seat frame, which will accept a T bolt. A T-slot fastener kit provides a means to mount supports directly to slotted seat rails (see Figure 6). They are suitable for use with Type E and F frameworks shown in Figure 1. (Video6).

Figure 6. T-slot fastener kit

As we have seen in Figure 1, wheelchair tubing can come in a wide range of tubing sizes, and you will need to know the diameter of the tubing, or the track widths for the extrusions, to ensure that you have the right mounting hardware.

Bodypoint has created a useful gauge for measuring these variables (Figure 7) if you do not have the wheelchair manufacturer’s paperwork at hand.

BES Healthcare has a limited number of these gauges to give away, if you would find one useful. Please contact info@beshealthcare.net to request your gauge.

References

- BS 8625:2019 Selection, placement and fixation of flexible postural support devices in seating. Specification.

- Circular clamp www.youtube.com/watch?v=Jlpru7xEpRg

- Frame clamp www.youtube.com/watch?v=_9M_N_lec7k

- Band clamp www.youtube.com/watch?v=TS0Eqqj-QVI

- Seat tube mounting brackets www.youtube.com/watch?v=N2iLDOqaKrI

- T-slot fastener kits www.youtube.com/watch?v=sqavsqP2Rws

- For the full range of Bodypoint videos, go to www.youtube.com/c/BodypointInc/videos