Categories

Speciality Areas

Pressure Care Materials

In the beginning there were old materials with old benefits, then there were new materials, some still with the old benefits, and now we have new materials with new benefits.

Petrochemical-based products proliferate in the present-day pressure care environment. Many of these may be as effective or more effective for pressure care as products made from natural materials, but many of them can present other challenges ranging from manual handling, to decontamination, to disposal challenges.

What options are out there?

There was a time when sheepskin was used extensively, and effectively, for pressure care for all ages from neonates to geriatrics. As awareness increased around the needs of infection prevention, it became clear that traditionally tanned sheepskins would not stand up to the traumas of washing at high temperatures to kill the bugs. This spawned the production of artificial sheepskins with polyester or nylon fibres being spun onto an artificial backing.

Old materials – old benefits

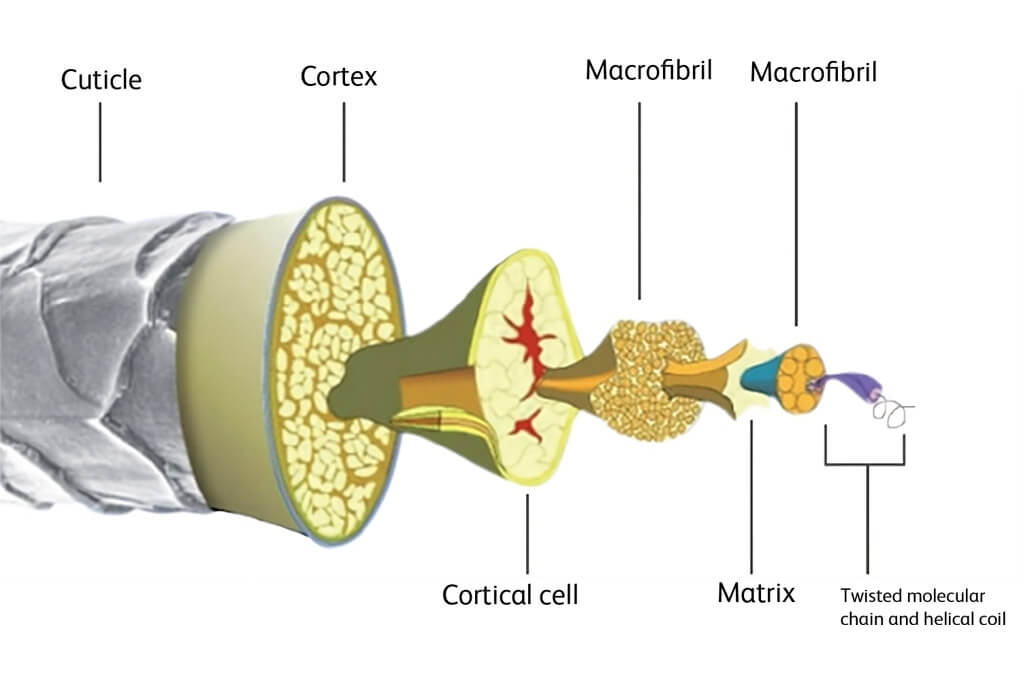

Unfortunately these artificial sheepskins were not very effective, and rightfully were deprecated within the NICE guidelines a while back. So why were they not effective? The reason is that man has not been able to replicate the complex structures of natural wool (Figure 1), and the man-made materials were unable to provide the skin care benefits of natural wool products.

The core of a wool fibre has a helical structure which gives its resilience and bounciness. Around this helix, there’s a further six layers of material, including cortical layers which are hydrophilic (unlike man-made materials that repel moisture) which will take up to a third of their weight in water vapour without feeling wet. The result is that the higher the density of the wool, the lower the relative humidity at the skin.

The outermost layer, the cuticle, allows the fibres to slide over each other, aiding shear reduction. For pressure care, the degree that the substrate can allow for skin envelopment is dependent on the density of the fibres – again an area where artificial sheepskins traditionally have been very poor, but merino-cross sheepskins are very good.

So what changed?

In Australia the CSIRO developed a new tanning process, and a new standard (AS4480.1:1998) was published, from which manufactures are able to make what are known as Hi-temp UR ‘medical’ sheepskins. These skins can be washed with wool wash detergents at up to 80°C. Also the process makes the skins urea-resistant (we secrete urea into our sweat from protein breakdown, and this causes hardening of the pelt in untreated skins).

A number of large-scale clinical trials have shown these medical sheepskins to be effective in reducing the incidence of pressure ulcers in various bed-bound populations. As a result NICE updated their guidelines to indicate that medical sheepskins were an effective pressure care tool. Alongside this the MDA (as it was before being merged into the MHRA) produced a report on bed overlays which showed that medical sheepskins were up in the ‘best in class’ for heel pressure reduction and heat transfer properties when tested alongside overlays made of man-made materials. An important benefit is that these medical sheepskins do not look like medical devices in use, and thus may be more acceptable to patients particularly in the home setting.

Alongside this, Healthcare Innovations Australia developed a technique where they were able to manufacture a ‘spun’ sheepskin with higher density wool than sheep were able to do, providing a product (Shear Comfort XD1900) that could be washed even with enzymatic detergents and at up to 90°C, and provided better microclimate properties than natural sheepskins. So, there we have gone full circle back to old materials – old benefits.

New materials – old benefits

Air-based products have provided good envelopment and pressure redistribution for pressure care. Air has been encapsulated in either air-tight pockets, or in foam. Foam is a good ‘air carrier’ since there is no danger of air loss from puncturing, and even today it is still a relatively inexpensive material. But it does have its disadvantages. It is relatively heavy, especially in a mattress. It is susceptible to contamination, and even if protected by a waterproof lining, the lining can get punctured and we get what is known as strikethrough. The ‘air holding’ properties of foam can also cause heat trapping which can cause the user to feel hot and cause sweating which adversely affects the skin microclimate and increases the risk of skin breakdown.

Normally foam cannot be cleaned, and therefore, ends up being consigned to landfill or incineration. (Even this creates a problem in that clinically contaminated items have to be disinfected before being transported to a waste site.) Incineration of foam mattresses needs specialist installation because of the release of hydrogen cyanide gases.

There is more to skin care than just pressure redistribution. The microclimate around the skin is important, and it is important that heat is dissipated and moisture wicked away. The behaviour of the support surface to absorb shear forces is also important.

New materials – new benefits

What alternatives to foam are there for cushions and mattresses that can tick all the boxes for skin health, manual handling challenges, infection prevention, and also being fully recyclable? One alternative is 3D spun thermoplastic elastomers – of the type to be found in the NEST pressure care products2.

For skin health, the NEST can provide comparable pressure care as a foam cushion or mattress, but also the 3D random loop structure of the polymer web absorbs various of the shear strains under the skin tissues. The open structure allows for heat and water vapour dissipation. The structure is maintained in use and provides a ‘springiness’ which facilitates movement, enabling turning in bed or movement on a cushion, thereby offering further pressure redistribution properties and aiding independence.

From the carers’ point of view, the light weight means that NEST mattresses can be lifted and turned by a single person, providing a major manual handling advantage.

Infection prevention

On the infection prevention front the elastomer has been shown to inhibit bacterial growth. Even more important is that both the cover and the core can be processed in washing machines: the core material can also be sterilised at temperatures of 100°C or more, without damaging the plastic.

The NEST is a CE marked Class I medical device. As was implicit under the Medical Device Directive (MDD) and explicit in the more recent European Medical Device Regulations (MDR), a medical device washer needs to be a CE marked Class I medical device itself, and disinfectants need to be themselves at least CE marked Class IIa medical devices. If instead of using a chemical disinfectant, you are using a machine that provides thermal disinfection, then that machine also needs to be a CE marked medical device at the Class IIa or higher level.

Sustainability and environmental credentials

Not only can the NEST be washed and disinfected when soiled, and between uses, the core material at end of life can be chopped up and recycled into new plastic products, and thus avoid the need to go to landfill. The NHS in the UK, and procurement bodies around the world in tender documents are increasingly seeking out and specifying sustainable offerings. This is yet another of the multiple boxes that the NEST ticks.